On January 16, 2023, the press conference of the new energy version of the TimesAI deep learning development platform independently developed by Dihuge was held in Changping International Innovation Port, Dongguan. At the same time, the unveiling ceremony of the new campus of Dihuge Dongguan Company and the new meeting place of the Dongguan Alumni Association of USTC were held. President Ping Tong of the Dongguan Alumni Association of USTC and key members of the Alumni Association, Yuchang Liu, secretary of the Party Committee of Changping Town, and the principals of various agencies, customers, partners, and a number of media witnessed this important moment.

At the press conference, Chairman and CEO Dr. Bin LingHu explained the international and domestic industrial development trends in 2023, especially emphasizing that the future of industrial AI requires an all-round industrial AI platform. As a result, Dihuge cooperated with the Hefei Institute of Material Science of the Chinese Academy of Sciences, gathered more than 200 cutting-edge AI algorithm talents and AI engineering teams, and after years of scientific research and development and engineering practice, launched the industry's top industrial AI engine product - TimesAI depth The learning and development platform is currently widely used in 3C, li-ion, photovoltaic, semiconductor and other industries.

Dihuge is an industrial AI platform company focusing on the research and development of deep learning algorithm platforms and intelligent equipments. Its main products include a series of products such as TimesAI deep learning development platform and AI digital factory, which are mainly used in industrial product appearance defect inspection, manufacturing big data calculation, production forecast and decision-making, etc.

For a long time, Dihuge has been adhering to the use of artificial intelligence technology to empower production and manufacturing, and through intelligent means to open up the whole chain elements of traditional industrial production, to better promote the digital, intelligent, and unmanned transformation of the manufacturing industry. Dihuge has 4 subsidiaries in Dongguan, Guangzhou, Suzhou, and Shanghai, and has a large-scale project base in Chengdu. Rooted in the Pearl River Delta, the Yangtze River Delta and the central and western regions, it is convenient to provide manufacturing customers with integrated software and hardware solutions and timely and responsive after-sales services.

In 2018, Dihuge entered the 3C industry, using deep learning technology to carried out the appearance defect inspection of 3C precision parts, mainly used in stamping, die-cutting, CNC, welding, injection molding and other products. For the first time, it solves the detection of planar and three-dimensional mobile phone handset meshes and the inspection of mobile phone breathable membranes under complex backgrounds, filling the technical gap in the industry.

In 2021, Dihuge will enter the field of li-ion, and complete vision applications in the multi-process segments of lithium battery manufacturing, such as coating, winding, slitting, lamination, liquid injection, and packaging, so that the production process can use machine vision to improve efficiency, Improve product quality. Dihuge has served Cosmx, GanfengLithium, Putailai and many other well-known enterprises in the industry.

TimesAI inspects more than one billion products

TimesAI is a development platform independently developed by Dihuge based on machine vision and deep learning. The platform has built a 2D/3D vision algorithm library, a deep learning self-training platform, an industrial product defect library, and an industrial robot communication library, which can complete product appearance defect inspection, defect data classification and real-time feedback with high precision.

Up to now, the number of products tested by Dihuge's engineering projects has reached more than one billion, and a large amount of industrial data has been accumulated for TimesAI's brain-like deep learning model. Within a short period of time, the upgrade of the algorithm model was completed to meet the AOI needs of various products and fast iterations in industries such as 3C and Li-ion.

During the project implementation process, TimesAI has improved the work efficiency of project deployment and implementation. At the same time, through data collection, analysis, and feedback, a closed loop of quality management for industrial production is formed, which provides a powerful tool for production control and improves product production efficiency, product yield, and the intelligence of production units.

How TimesAI Empowers Lithium Industry

In an important part of this press conference, Dr. Peng Xu, CTO of Dihuge, explained the characteristics of the new energy version of the TimesAI deep learning development platform. This version can cover the visual application requirements of mainstream processes in the front, middle and back stages of lithium battery manufacturing. The functional design conforms to industry standards, supports zero-code drag-and-drop project development, provides 21 categories of visual algorithms and hardware interfaces, and supports python and C++ languages. secondary development.

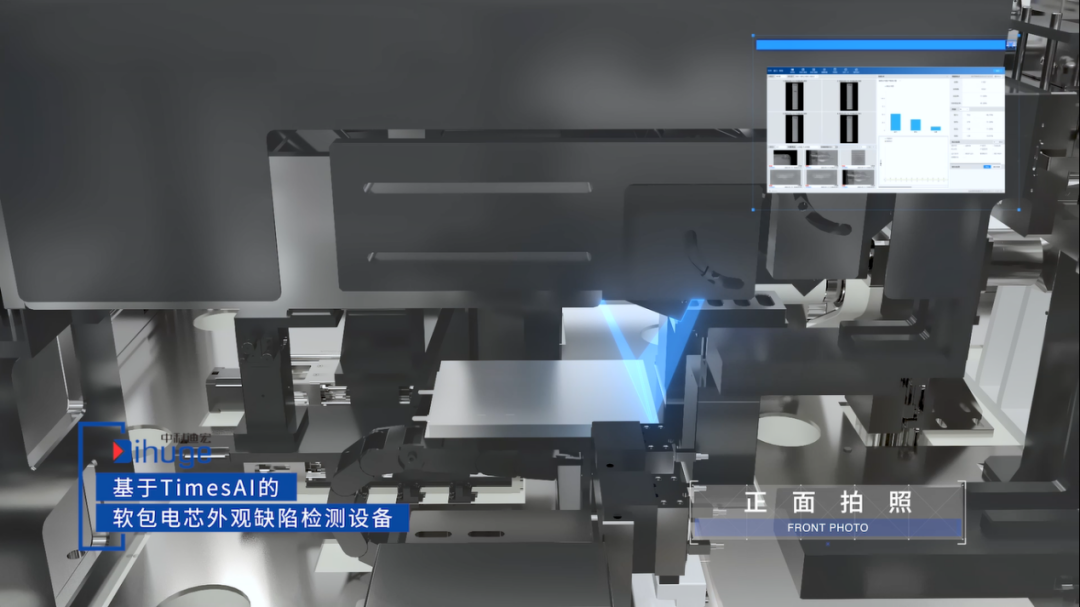

Dr. Peng Xu said that the technical team of Dihuge used the TimesAI new energy version to complete the unmanned full inspection of the surface and corner defects of pouch cell for the first time, and all indicators met the mass production standard.

In terms of reliability, TimesAI New Energy Edition can locate unsupervised abnormal defects. For extremely sporadic safety product defects, an abnormal inspect model is established based on good products to avoid the outflow of defective products. Simultaneously run the exception classification mechanism, flexible configuration of multi-level exceptions, and automatic classification of new exceptions.

In terms of performance, TimesAI New Energy Edition can achieve automatic optimization of algorithm efficiency, automatic optimization of algorithm key parameters, automatic compression of deep learning models, adaptive optimization of operating efficiency, and automatic allocation of computing power based on hardware and computational complexity.

In terms of standardization, TimesAI New Energy Edition supports multi-track and winding mode guided configuration, provides a variety of control templates that meet industry standards, and can also use single-step guided configuration to standardize the process. Thereby promoting industry quality quantification standards and realizing traceable data management.

Dr. Peng Xu emphasized that TimesAI can accelerate the development of AOI equipment, promote the quantification and standardization of lithium product defects, and empower the equipment at the same time.

The products released this time also include the TimesAI deep learning cloud platform, which can build a private cloud platform at the customer site and integrate functions such as model training, data management, and multi-point deployment. This large-scale use method can effectively reduce hardware and management costs, realize centralized storage, and facilitate query and data traceability.

Continuous forging product competitiveness

Xin Tong, an outstanding alumnus of USTC and a researcher at the Institute of High Energy Physics of CAS, mentioned in his speech that AI may lead the next generation of industrial revolution and play an extremely important role in the development of human society. He emphasized the importance of the integration of AI technology and personnel for solutions, and predicted that AI is still in its initial stage of development, and will expand rapidly in the next two decades, and AI technology will also show an unprecedented appearance. Finally, researcher Xin Tong expressed full confidence in the future development of Dihuge.

For a long time, Dihuge has maintained cooperation with institutions of higher learning at home and abroad to implement the research results into engineering.

At this press conference, Dr. Haoran Duan from Durham University in UK introduced the current application results of deep learning. Traditional detection and segmentation techniques can effectively identify objects, but require a large amount of data and annotations. Data collection and labeling are expensive, also for anomaly detection of industrial defects.

Dr. Haoran Duan shared the latest work content based on unsupervised anomaly detection, which can help industrial AI accurately locate and identify abnormal defects with the least amount of manpower and material resources. Based on this paradigm, further optimization can be done, such as data cleaning and enhancement, fine feature learning, and model efficiency improvement. These new scientific research achievements will soon be integrated into Dihuge's TimesAI deep learning development platform and applied in specific AOI projects.

This press conference is a new start for Dihuge. In the future, Dihuge will drive the joint development of the industry with its own development, continue to deepen the field of artificial intelligence, continuously iteratively optimize the TimesAI platform, and promote the development of the entire new energy industry. Intelligence continues to advance.