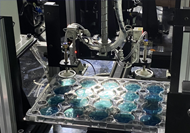

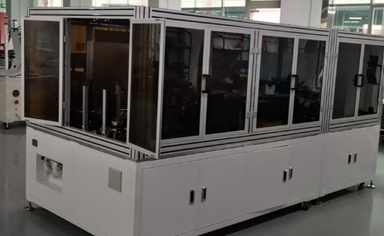

The solution is based on the Dihuge TimesAI deep learning development platform, which integrates CV+AI+Automation to achieve online real-time inspection of the

back cover of the wireless charger, integrated services such as defective product classification, screening and rejection, data analysis and statistics, and can be iteratively

optimised in the inspection process.

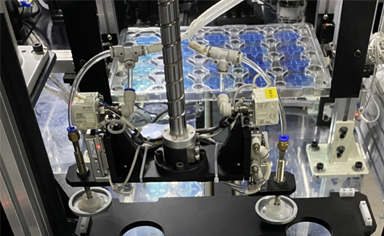

The solution effectively solves the three major difficulties in the field: 1, the probability of occurrence of different types of defects gap is large, the defect sample is not

balanced. 2, the defects are tiny target defects. 3, the semantic hierarchy of defect types.

At present, it covers dozens of defect types, such as: top R angle pressure wound, scratch, hole deformation, hole pressure wound, inner bottom surface scratch, inner

step surface pressure wound, outer side wall deformation, outer side wall sanding mark, outer side wall knife pattern, outer side wall scratch, outer side wall collapsed

edge, outer bottom pit, outer bottom knife pattern, outer bottom collapsed edge, inner knife pattern, top R angle is not fully turned, hole burr, outer bottom pit, bad

teeth, shallow teeth, light holes, incomplete cutting Roughness on the reverse side, knocking on the reverse side, burnt inside the hole, bruising on the outer circle,

foreign objects in the hole, etc.